Products

Magneto Coated Titanium Anode

MAGNETO special anodes B.V. was founded in 1957 under the name of MAGNETO-CHEMIE B.V. and is the original inventor and manufacturer of Titanium anodes with Platinum and Ruthenium coatings. The steady growth of the production and the continuous development of inert anodes have given MAGNETO-CHEMIE B.V. a prominent position in the market for Titanium anodes.

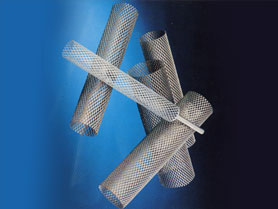

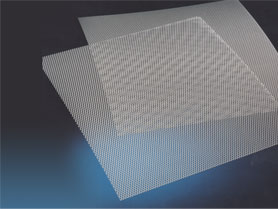

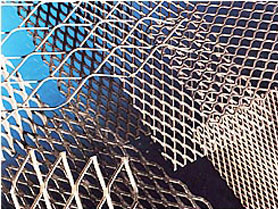

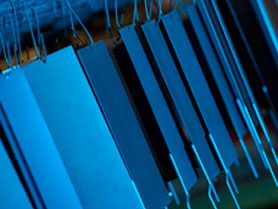

Because of a very flexible production facility, we are able to manufacture anodes of all types: sheet, plate, mesh, wire, rod, tubular or combinations and/or assemblies of these materials. Their size and number vary from several cm2 to 2 m2 and from 1 to 10,000 pieces. The process in which the anodes are used determines size, shape and coating specification of an anode.

Important parameters determining the anode design are:

â—† The electrochemical cell or installation wherein the anodes are used

â—† The process conditions, such as electrolyte composition, temperature, current density, design life, etc.

â—† Mechanical load of the anode

â—† Capacity of electrical conductivity of the base material.

All anodes are produced according to customer specifications. When these specifications are not yet completely determined, our engineers are pleased to use their knowledge and experience to finalise the design together with the customer.

|

Main application areas |

Anodes and coatings |

Details |

|

Cathodic Protection |

KERAMOX® Titanium anode Platinised Titanium Anodes based on Niobium or Tantalum |

All round applicable At high current densities, for example in sea water High voltages or strongly corrosive electrolytes |

|

Seawater electrolysis |

KERAMOX® Titanium anode Titanium with a Ruthenium Mixed Metal Oxide coating Titanium with a Platinum-Iridium Oxide coating |

Depending on amongst others temperature and salinity |

|

Electroplating |

Titanium with an Iridium Mixed Metal Oxide coating Platinised Titanium |

In highly acidic environments such as: Electro galvanising (zinc plating) Anodising of Aluminium Chromium, Nickel,Tin, etc. plating Precious metal plating Reverse pulse Copper plating Hard Chromium plating Precious metal plating |

|

Water treatment |

Platinised Titanium Titanium with an Iridium Mixed Metal Oxide coating Boron-Doped-Diamond anodes |

Electro dialysis with polarity reversal Recovery of metals Oxidation and break-down of organic contaminations Higher overpotentials,amongst others for disinfection |

|

Hypo chlorite & Disinfection |

Titanium with a Ruthenium Mixed Metal Oxide coating Titanium with an Iridium Mixed Metal Oxide coating Titanium with a Platinum-Iridium Oxide coating |

Depending on salinity, polarity reversal and current density |

|

Synthesis reactions |

Platinised Titanium Titanium with an Iridium Mixed Metal Oxide coating Boron-Doped-Diamond anodes |

Depending on the particular reaction At higher overpotentials

|

|

Hydrogen production |

Nickel electrodes with a precious metal coating |

Coating process by means of exchange plating The purpose is to decrease the overpotentials |